D. Octal CNC

|

IGG uses CNC milling to manufacture some of the parts it makes. The CNC machine was bought

as a bare bone construction, which means it came without an external communication port

and can be programmed only via a small built-in touch screen. To cut the costs even more,

IGG bought the cheapest firmware - the one that doesn't include an advanced user interface.

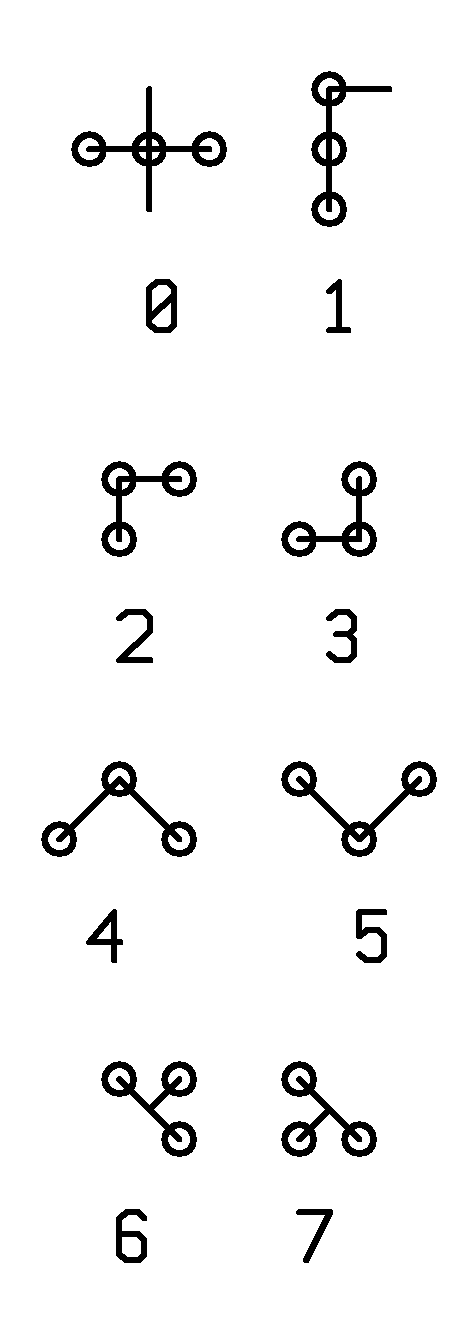

Engineers program the CNC using octal digits drawn as strange glyphs on the display.

The engineers often write down their programs on paper, as that's the only way backing up their data. A lot of valuable CNC programs are stored this way. This is clearly not compliant with the policy the quality assurance auditors will mandate. The only solution is to finally convert the programs into conventional numbers, stored in text files. Unfortunately, due to the amount of data and the short deadline, this is not feasible to do by hand. The engineers used their off-work hours to scan the papers - everything is now available in high resolution gray scale bitmaps. The only missing step is to process the images and convert the symbols into numbers. |

canonical form of the digits |

There are 8 digits, from 0 to 7. The canonical printed forms are as given above - hand written symbols may be less perfectly shaped. Each digit consists of 3 circles and 2 lines.

Input

A grayscale png with multiple "handwritten" lines of octal digits (black ink on white paper that may have texture) with the following properties:- maximum size of a page is 16384*16384 pixels;

- digits may be scaled, aspect may change;

- digits may be rotated randomly, within +-15 degrees;

- spacing between characters are not even, but lines or cirles of different characters never cross or touch;

- lines of text are not always straight;

- each line ends with a checksum digit.

Output

Outpout is a stream of digits from '0' to '7' in ASCII text, checksum included. The output shall cosist exactly as many digits as many gylphs are on the input png. The evaluator will ignore empty lines and white space.Example input

A small "hello world" example is provided as example.png among with the input files. File reference_digits.png contains a list of digits from 0 to 7, without checksum, written in a relatively clean form (actual input images may have more distortion).Example output

Output of the "hello world" example:0421501451541541570425 0421671571621541440423